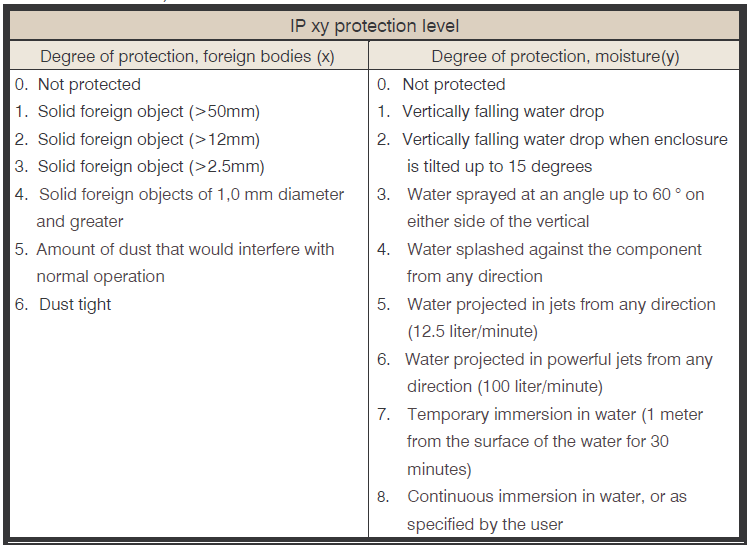

ANYSOAR has incorporated dust proofing and water proofing into majority of its LED power supply design. Mainly based on the international standard IEC60529, detailed descriptions can be found in the following table:

(Note: PSUs with IP64 rating or above are suitable for indoor or outdoor applications in sheltered locations) *IP64-IP66 level and IP67 with potentiometer products are suitable for damp indoor or sheltered outdoor environment. For actual installation limitations, please refer to the corresponding IP level tests.

*IP64-IP66 level and IP67 with potentiometer products are suitable for damp indoor or sheltered outdoor environment. For actual installation limitations, please refer to the corresponding IP level tests.

*All products cannot be continuously submerged in water.

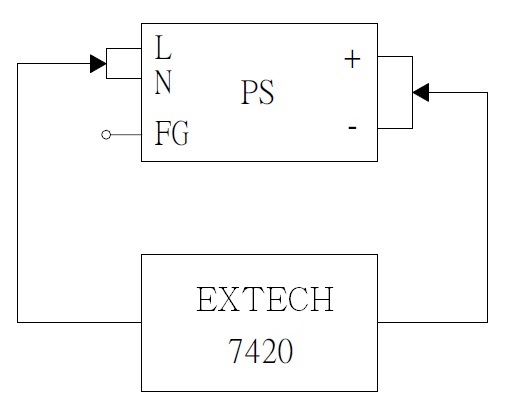

Indicates Hi-Pot Test or Electric Strength Test. The input should be shorted together as well as the output before test. The test will proceed under particular loop, such as I/P-O/P, I/P-FG and O/P-FG with certain high voltage value for 1 minute. (The typical leakage current is 25mA when testing with AC)

1. Hi-Pot Test is a way to ensure if the isolation between primary to secondary is done properly, preventing damaging to S.P.S. when facing high voltage between input and output. The test voltage should be gradually increased from 0V to preset level and remains at preset level for 60 seconds with raise time greater than 1 second. In mass production, the test period could be reduced to 1 second. If the leakage current flowing through the isolation material increases rapidly when applying test voltage, it indicates ineffectiveness of isolation (dielectricbreakdown). Corona effect/discharge or transient electrical arc is not considered as failure.

2. When AC test voltage is applied, Y capacitors are the main cause of leakage current. A 4.7nF capacitor can cause leakage current of 5mA. According to regulations of UL-554, the Y capacitors should be removed for Hi-Pot test, which is not practical for mass production. The only solution is to increase the leakage current setting, typically 25mA, of test instrument. Presently, the criteria of leakage current are not defined in safety regulations.

3. According to regulations of IEC60950-1, DC test voltage can be substituted when there are bridging capacitors coupled between primary and econdary circuits, so as to solve the problem of leakage current.

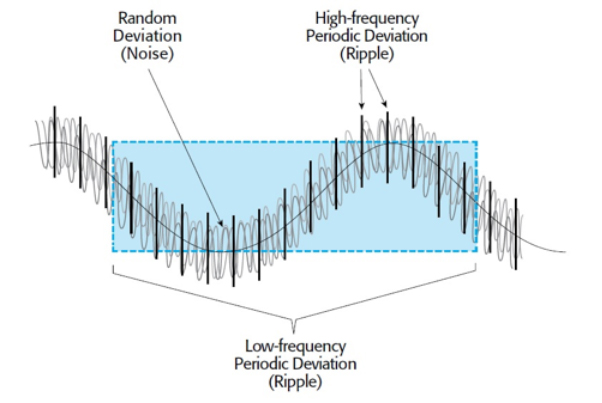

An AC waveform can be identified on the DC output of a LED Drivers, which is shown in there are two AC components, also known as Ripple and Noise (R&N) on the DC output. The first one, coming from sine wave rectification, is at a low frequency which is 2 times of the input frequency; the second one is at high frequency which is from the switching frequency. as shown in Figure 1.

Figure 1. Component of AC form:

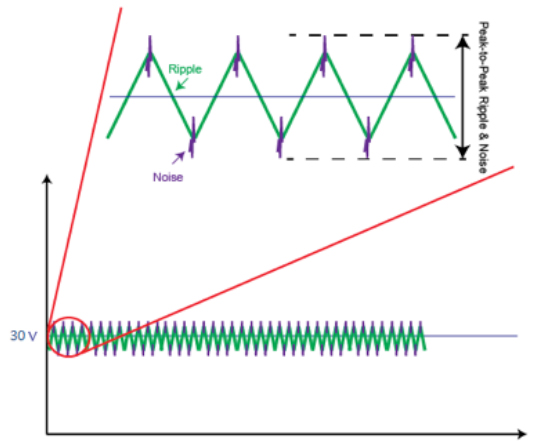

The ripple exists because, during a portion of the converter’s operating cycle, energy is transferred to the secondary from the primary and the output voltage increases slightly. During the time interval when there is no energy transfer to the secondary, the load current is supplied by stored energy in the output capacitance and inductance of the converter, and the output voltage decreases slightly as this energy is depleted. Ripple is a low frequency component and will be occur at the same as the converter operating frequency, or some multiple thereof. Noise is much more variable and harder to predict than ripple. It is caused by ringing in parasitic inductances due to the large values of di/dt that occur internally in a switching converter. The noise is much higher frequency than the ripple and can be up into the MHz range. Noise occurs in the form of “bursts” at the time of switching activity in the converter, so therefore appears to be superimposed upon the peaks and valleys of the ripple waveform as shown in Figure 2.

Figure 2. Output Ripple & Noise:

When current drawn exceeds the rating of the PSU, the protection circuit will be triggered to protect the unit against overload/overcurrent.

Protections of overload/overcurrent can be divided into several forms:

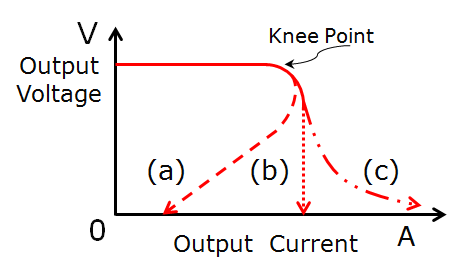

(1)FOLDBACK CURRENT LIMITING

Output current decreases about 20% of rated current, shown as curve (a) in the figure below.

(2)CONSTANT CURRENT LIMITING

Output current remains at a constant level and within the specified range while the output voltage drops to a lower level, shown as curve (b) in the figure below.

(3)OVER POWER LIMITING

Output power remains constant. As output load increases, output voltage decreases in proportion, shown as curve (c) in the figure below.

(4)HICCUP CURRENT LIMITING

Output voltage and current keep pulsing ON and OFF repeatedly when protection is activated. The unit automatically recovers when faulty condition is removed.

(5)SHUT OFF

Output voltage and current are cut off when output load reaches protection range.

NOTE: Protection mode of some of the products combines with different types of the forms mentioned, such as constant current limiting + shut down.

Recover method:

Recover method:

(1)Auto Recovery: PSU recovers automatically after faulty condition is removed.

(2)Re-power on: PSU restarts by manual AC re-power on after faulty condition is removed.

Note:Please do not operate PSU in overcurrent or short-circuit condition for a long period of time to prevent a shorten lifespan or damaging the PSU.

MTBF (Mean Time Between Failure) and Life Cycle are both indicators of reliability. MTBF can be calculated by two different methodologies, which are “part count” and “stress analysis”. The regulations, MIL-HDBK-217F Notice 2 and TELCORDIA SR/TR-332(Bellcore) are commonly used to calculate MTBF. MIL-HDBK-217F is a United States military standard, and TELCORDIA SR/TR-332(Bellcore) is a commercial regulation. ANYSOAR utilize MIL-HDBK-217F(Stress Analysis) as the core of MTBF. The exact meaning of MTBF is, after continuously using the power supply for a certain amount of time, the average time that the probability of proper operation is down to 36.8%(e-1=0.368). Currently ANYSOAR is adopting MIL-HDBK-217F, forecasting the expected reliability through Stress Analysis (excluding fans); this MTBF means the probability of the product can continue the normal work after working continuously up to the calculated MTBF time is 36.8% (e-1=0.368). If the power supply is continuously used at double the MTBF time, the probability of proper operation becomes 13.5%(e-2=0.135). Life Cycle is found by using the temperature rise of electrolytic capacitors under maximum operating temperature to estimate the approximate life of the power supply. For example, RSP-750-12 MTBF=109.1K hours(25°C); electrolytic capacitor C110 Life Cycle=213K hours (Ta=50℃)

DMTBF(Demonstration Mean Time Between Failure) is a way of evaluate MTBF。Please refer to the following equation for MTBF calculation.

Where

MTBF:Mean Time Between Failure

X2:Can be found in chi-square distribution

N:Number of sampling

AF:Acceleration factor, which can be derived from acceleration factor equation.

Ae=0.6

K(Boltzmann Constant)=(eV/k)

T1:Rated temperature of specification. Note: Kelvin will be the unit use for calculation

T2:The temperature that is used in the meaning of acceleration, and the chosen temperature could not result in physical change in materials. Note: Kelvin will be the unit use for calculation.

Power Factor Correction or PFC is to improve the ratio of apparent power to real power. The power factor is around 0.4~0.6 in non-PFC models. In models with PFC circuit, the power factor can reach above 0.95. The calculation formulas are as follows: Apparent Power=Input Voltage x Input Current (VA), Real Power= Input Voltage x Input Current x Power Factor (W).

From the point of view of environment friendly, the power plant needs to generate a power which is higher than apparent power in order to steadily provide electricity. The real usage of electricity is defined by real power. Assuming the power factor is 0.5, the power plant needs to produce more than 2WVA to satisfy 1W real power usage. On the contrary, if the power factor is 0.95, the power plant only needs to generate more than 1.06VA to provide 1W real power, It will be more effective in energy saving with PFC function.

Active PFC topologies can be divided into single-stage active PFC and two-stage active PFC, the difference is show as the following:

Single-stage active PFC ( Single )

Two-stage active PFC ( Two )

Advantage:

Single : Low cost , Simple schematic , High efficiency in small watt application

Two : High efficiency , Higher PF , Easy feedback control , High adoptive against load condition

Disadvantage:

Single : Huge Ripple complex feedback control

Two : Higher cost , Complex schematic

Limitation:

Single :

1.Zero “hold up time”. The output is affected by the AC input directly.

2.Huge ripple current results in lower LED life cycle.(drive the LED directly)

3.Low dynamic responds, easily affected by load.

Two : Suitable for all kinds use

At input side, there will be (1/2 ~1 cycle, ex. 1/120 ~ 1/60 seconds for 60 Hz AC source) large pulse current (20~100A based on the design of S.P.S.) at the moment of power on and then back to normal rating. This "Inrush Current" will appear every time you turn on the power. Although it will not damage the power supply, we suggest not turning the power supply ON/OFF very quickly within a short time. Besides, if there are several power supplies turning on at the same time, the dispatching system of AC source may shut off and go into protection mode because of the huge inrush current. It is suggested that these power supplies start up one by one or use the remote control function of S.P.S. to turn them on/off.

In general there are two circumstances that will cause the power supply to shut down.

The first one is the activation of the over-load-protection (OLP). To deal with this situation, we suggest increasing the rating of the output power or modifying the OLP point.

The second one is the activation of over-temperature protection (OTP) when the internal temperature reaches the pre-set value.

All of these conditions will let the S.P.S. enter protection mode and shut down. After these conditions are removed, the S.P.S. will be back to normal.

1. To increase the reliability of the S.P.S., we suggest users choose a unit that has a rating of 30% more power than actual need. For example, if the system needs a 100W source, we suggest that users choose a S.P.S. with 130W of output power or more. By doing this, you can effectively boost the reliability of the S.P.S. in your system.

2. We also need to consider about ambient temperature of the S.P.S. and whether there is additional device for dissipating the heat. If the S.P.S. is working in a high temperature environment, we need to make some derating to the output power. The derating curve of "ambient temperature" versus "output power" can be found on our spec sheets.

3. Choosing functions based on your application:

Protection function: Over Voltage Protection (OVP), Over Temperature Protection (OVP), Over Load Protection (OLP), and etc.

Application function: Signaling Function (Power Good, Power Fail), Remote Control, Remote Sensing, and etc.

Special function: Power Factor Correction (PFC), Uninterruptible Power Supply (UPS) function.

4. Make sure that the model qualifies for the safety standards and EMC regulations you need.

For Gas Chargers , Cylinders : Quantity for 1x20' Container.

For Dispeners and Siphons : 1000PCS.

We only sell B2B as an exporter to wholesalers, never directly to small businesses or retail customers.